FRÖMAG Broaching MachineI

FSR Serisi

Features

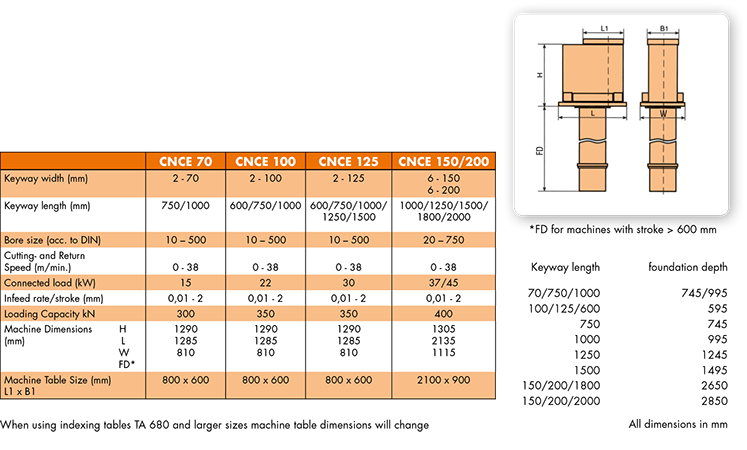

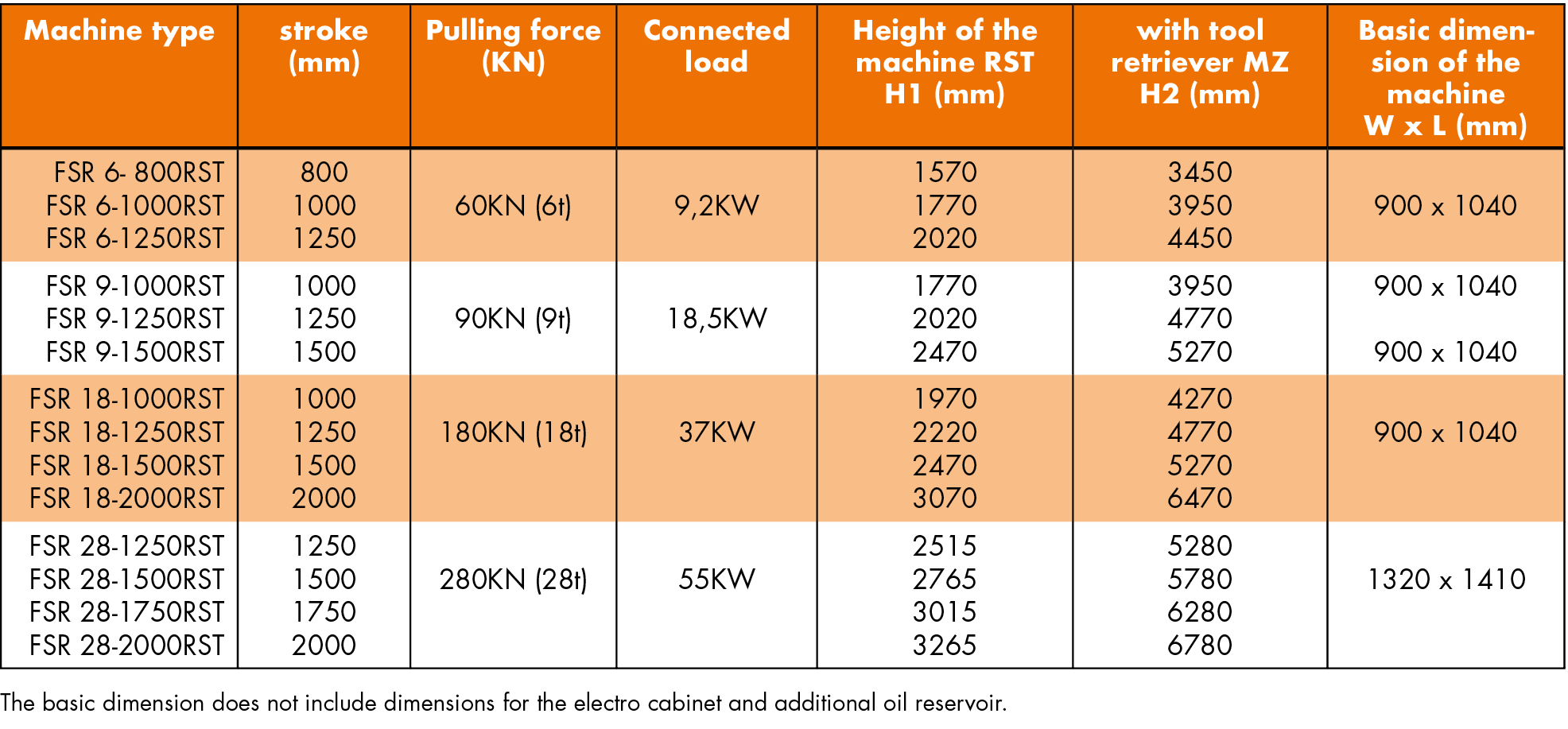

Electromechanical vertical internal broaching machines FSR, guarantee high efficiency and low production cost due to their special design. The pull bridge of the machine is designed to accept broach holders according to the different standards. The ball screws used for the stroke movement of the pull bridge as well as the additional hardened and ground guide columns, result in a connection with the DC-motors for a smooth and rigid running performance of the machine.

Additional equipment offered such as the retriever, shim control, and moveable table, ease machine operation and facilitate automatic machine performance as well as the use of machines in transfer lines.

Highlights:

- Highly productive

- Economic

- Space saving

- Versatile

- Fully automated operating cycle

- Automation

- Interlinking

FTR Serisi

Features

Contrary to conventional broaching machines, the broaching tool stays stationary and the moving table including the workpiece and workpiece clamping is moved relative to the broaching tool. FRÖMAG electromechanical driven FTR broaching machines ensure cost effectiveness and efficiency. Because of the ergonomic construction, the machines can be placed at ground level and do not need a foundation pit. They can be operated without additional platforms or pedestals. The FTR broaching machines can be set up as stand-alone machines with either manual or automated feed. They can also be fully integrated into machining cells applying robotics and handling devices.

Highlights- Installable at ground level

- Ergonomic design

- Energy efficient

- Space saving

- Profitable

- High level of performance

- Fully automated applicable

- Automation

- Interlinking