GLEASON CYLINDRICAL GEAR SOLUTIONS

Functional Measuring Instruments

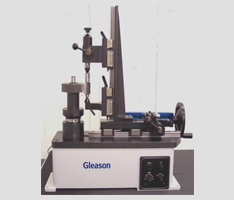

GRS-2

- Efficient and reliable functional testing

- Accurate and affordable production process control

- Windows based, user friendly software

Gleason Metrology Systems robust and reliable double-blade threaded roller systems are ideal for use in workshops or inspection laboratories. Choose from the simplest manual (manual) dual-spindle wheel mill, pointed motorized model or motorized version with integrated Gleason Metrology Systems Dual Side Analysis Software. For powder metal and plastic gear manufacturers, Gleason Metrology Systems provides an optional force measurement detection slide configuration that includes a force gauge for true test pressures.

PC-based Gleason Metrology Systems The Two-Sided Analysis Software allows the user to create tolerances on total composite, tooth-to-tooth and strikeout parameters to determine if the components are within specification. If a component is not specified, the software marks the value outside tolerance and rejects the fragment. Nickels are marked explicitly in the charts and nick values can be included or excluded in analysis calculations.

Both graphical and numerical results are displayed on the PC monitor. These results can be printed on standard paper so that the old-lane chart rollers can be removed from the center.

The software allows the operator to save test results in a database format (.csv file) that interfaces with existing SPC software.

Optional functional tooth thickness software development calculates the functional size of a component from narrow network center distance variations. This allows the average DOP values to be examined according to the tolerance levels to use the software bias feature to associate the results with the conventional DOP.