GLEASON CUTTING TOOLS AND WORKHOLDING

Cylindrical Gear Solutions

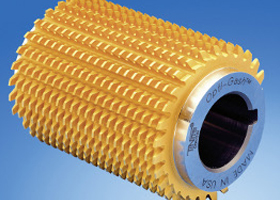

Opti Gash Hobs

Gleason Cutting Tools has been using the Opti-Gash® concept to help customers improve their gear hobbing processes for many years. The goal is to reduce the TOTAL cost per part, including the cost of buying, sharpening, coating and maintaining your tool, in addition to the actual machining processes.

Opti-Gash is the concept of increasing the number of hob gashes to allow an increase in the feed rate for a given chip thickness or given allowable scallop depth. Also, designing a hob with a smaller hob diameter allows a faster RPM at a given cutting speed (Surface Meters per Minute), and increased feed and RPM yields improved productivity.

- Optimized feed based upon chip load and/or scallop depth

- More gashes in the hob

- Allows higher feed or lower chip load

- Achieves a useable life of about 5-10 Sharpen and recoats

- Smaller hob diameter, yielding higher RPM

- Optimized cutting speed vs. hob material and coating

- Optimized shift strategy to keep the hob on the machine longer

- Evaluation of the application on a Total Cost per Part basis.

- Application at optimum parameters considering cycle time vs. wear