GLEASON CUTTING TOOLS AND WORKHOLDING

Cylindrical Gear Solutions

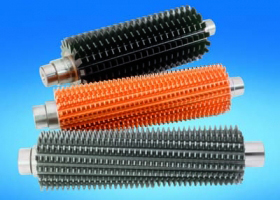

Wafer Hobs

If the concept of reducing the hob O.D. and increasing the number of gashes is taken to an extreme case, the result is a small diameter hob with so many gashes that the re is no sharpen able life remaining. This hob becomes a “Disposable” tool with no maintenance costs, and is the basis for the Wafer® hob concept.

Standard Wafer Hob sizes are 50 mm and 65 mm diameters, with 22 mm or 32 mm pilot diameter shank styles. Using a shank style tool allows for quick hob change, and minimizes the chance for hob mounting runout. The shank style allows for economical manufacturing as well as automatic loading and truing of the tool. The hob length is maximized for more shift positions. The Wafer Hob® is designed to be a high-speed, productive hob.

Some of the advantages to this concept are:

- With manufacturing control, size adjustment from one hob to the next is not needed.

- It is no longer necessary to sharpen the hob. Tool maintenance cost is therefore reduced to zero.

- Because tools are no longer sharpened the cutting faces and flanks are always fully coated.

- Tool inventory can be reduced since a float of tools waiting at the sharpener is no longer needed.

- Tool accuracy is completely in the hands of the tool manufacturer; it is not dependent on the customer’s sharpening ability.